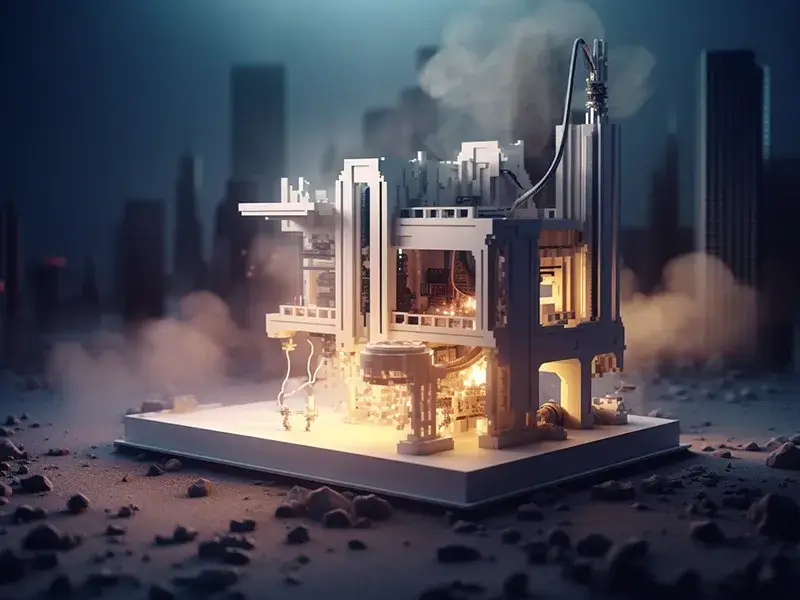

The construction industry has seen rapid advancements in technology, and 3D printing is one of the most promising. With the ability to print complex structures and designs, 3D printing is changing the way we build. From small-scale models to full-scale buildings, the possibilities are endless.

This innovative technology is already being used in various construction projects worldwide, and experts predict that it will become a necessary part of the industry in the near future. As 3D printing continues to develop, new training programs are emerging to meet the demand for skilled workers.

The construction industry is already facing a shortage of skilled labor, and 3D printing presents an opportunity to fill this gap. With the right training, workers can learn the technical skills required to operate 3D printers and use this technology to its fullest potential. As such, 3D printing has the potential to revolutionize the construction industry, not only in terms of design and efficiency but also in terms of workforce development.

Key Takeaways

- 3D printing is being used to construct a variety of buildings and structures, including houses, bridges, and staircases.

- Demand for new skills in 3D printing is increasing due to improved reliability and functionality of machines, as well as a net zero drive.

- Some companies are using 3D printing to develop innovative materials, such as graphene-enhanced concrete.

- Experts predict that 3D printing in construction will become more widespread and affordable in the coming years.

3D Printing Developments

Various countries and companies are making significant progress in the use of 3D printing in construction.

Icon, a construction technology company, is building the world’s largest 3D-printed housing development in Texas, while Dubai plans to have 25% of its buildings 3D printed by 2025.

The Netherlands, China, and Italy are competing to print the longest bridge, and in the UK, BAM recently installed a 3D-printed staircase for a footbridge over the M8 motorway.

Accrington, Lancashire, is set to become the biggest 3D-printed housing development in Europe, where we are constructing homes for veterans, homeless people, and low-income families.

In addition to housing, 3D printing is being used to test materials such as graphene-enhanced concrete on 3D-printed prototypes.

Versarien, a materials engineering company, is also launching 3D-printed pods for sale at just under £30,000.

The water industry and flood defense could also benefit from 3D printing, with the technology being used for temporary structures.

These developments indicate that 3D printing in construction is moving from the top of the pyramid, with low volume and relatively high costs, towards becoming a normal part of the construction process in the future.

Training and Skills

Training providers and educational institutions are stepping up efforts to develop new skills in response to the growing demand for 3D printing technology in the construction industry. This demand has been driven by several factors, including the improved reliability and functionality of machines, supply chain interruptions, and the net zero drive. As a result, there is a need for workers with expertise in 3D printing technology to design and produce innovative structures, materials, and components.

To meet this demand, training providers and educational institutions have launched courses and training programs that focus on 3D printing in construction. For instance, the Louth Meath Education Training Board in Ireland has launched the country’s first 3D concrete printing course, while the Advanced Manufacturing Training Centre of Excellence and innovation centre Future Cast held a two-day 3D Construction Printing training course. In addition, companies like Versarien are partnering with local training providers to develop skills on a wider basis and promote 3D printing as a cool career. The table below highlights some of the key training initiatives in this field:

| Training Provider | Course/Program | Focus |

|---|---|---|

| Louth Meath Education Training Board | 3D Concrete Printing Course | Concrete printing |

| Advanced Manufacturing Training Centre of Excellence | 3D Construction Printing Training Course | Construction printing |

| Future Cast | 3D Construction Printing Training Course | Construction printing |

| Versarien | Local partnerships with training providers | 3D printing skills development |

Overall, these initiatives are essential for equipping a new generation of workers with the necessary skills to build the future of construction through 3D printing technology.

Opinions and Predictions

According to industry expert Ricketts, the potential for widespread adoption of 3D printing in the construction sector has reached a tipping point, with the technology expected to become more commonplace in the coming years.

Currently, 3D printing in construction is at the top of the pyramid, with low volume and relatively high costs. However, as the technology is used more frequently, it will become more normal and affordable.

In a few years’ time, 3D printing in construction will be just another part of the building process.

Despite the potential benefits of 3D printing in construction, there are still challenges that need to be overcome.

The technology requires skilled operators, and there are still some restrictions on the size and complexity of objects that can be printed.

Additionally, there are concerns about the impact of 3D printing on traditional construction jobs. However, as the technology continues to evolve and become more widely adopted, these challenges are likely to be addressed.

In the coming years, 3D printing is expected to contribute to greater efficiency, sustainability, and innovation in the construction industry.

Frequently Asked Questions

What are the limitations of 3D printing in construction?

Despite its potential to revolutionize the construction industry, 3D printing still has several limitations that need to be addressed.

Firstly, the size of the objects that can be printed is limited by the size of the printer, making it difficult to 3D print large structures.

Secondly, the quality of the materials used in 3D printing may not meet the standards required for construction, and the durability of such materials is still uncertain.

Thirdly, 3D printing is still relatively expensive compared to traditional construction methods.

Lastly, there are concerns about the safety and regulatory issues surrounding 3D-printed structures.

However, with continued research and development, these limitations can be overcome, and 3D printing may become a viable option for the future of construction, providing greater design freedom and sustainability.

How does 3D printing in construction compare to traditional building methods in terms of cost and efficiency?

When comparing 3D printing in construction to traditional building methods in terms of cost and efficiency, it is important to note that currently, 3D printing is at the top of the pyramid with low volume and relatively expensive production.

However, as it becomes more widespread, it will move down the pyramid and become a normal, cost-effective method of construction.

Furthermore, 3D printing has the potential to significantly reduce waste and increase efficiency through the use of precise, digital designs and automated processes.

It also has the ability to produce unique and complex shapes that may be difficult or impossible to achieve with traditional building methods.

While the initial investment in 3D printing technology may be high, the long-term benefits in terms of cost and efficiency make it a promising option for the future of construction.

What are some potential environmental impacts of using 3D printing in construction?

The potential environmental impacts of using 3D printing in construction are multifaceted.

On one hand, 3D printing has the potential to reduce waste and carbon emissions by using precise amounts of materials and minimizing construction waste.

Additionally, the ability to print on site may reduce transportation emissions associated with traditional building methods.

However, the use of energy-intensive machinery and the potential for increased consumption of plastics and other materials could offset these benefits.

Furthermore, the long-term durability and environmental impact of 3D printed structures is unknown, and further research is needed to fully understand the potential environmental impacts of this emerging technology.

How do regulatory bodies view the use of 3D printing in construction, and what regulations are in place to ensure safety and quality?

Regulatory bodies view the use of 3D printing in construction with a cautious eye, as the technology is still in its early stages and requires strict safety and quality standards to be upheld.

In the United States, the Occupational Safety and Health Administration (OSHA) has issued guidelines for the safe use of 3D printing, emphasizing the need for proper ventilation, personal protective equipment, and machine maintenance.

The European Union has also established regulations for 3D printing, requiring manufacturers to adhere to safety and quality standards and to provide clear instructions for use.

In addition, various international organizations, such as ASTM and ISO, have developed standards for 3D printing in construction to ensure the safety and quality of printed structures.

As the use of 3D printing in construction continues to grow, it is important for regulatory bodies to continue to monitor and regulate the technology to ensure its safe and effective use.

What role do architects and designers play in the 3D printing construction process?

Architects and designers play a crucial role in the 3D printing construction process as they are responsible for creating designs that can be translated into 3D-printed structures. They must consider the limitations and capabilities of the 3D printing technology, such as the size and shape of the printer, the materials used, and the need for support structures.

Additionally, they must ensure that their designs comply with building codes and regulations while also meeting the client’s needs and preferences. Collaboration between architects, designers, and engineers is essential to ensure that the 3D-printed structures are structurally sound, aesthetically pleasing, and functional.

As 3D printing technology continues to advance, architects and designers must stay up-to-date with the latest developments and techniques to fully leverage its potential in construction.

Source: Construction Management